What Is a Dead End Strain Clamp?

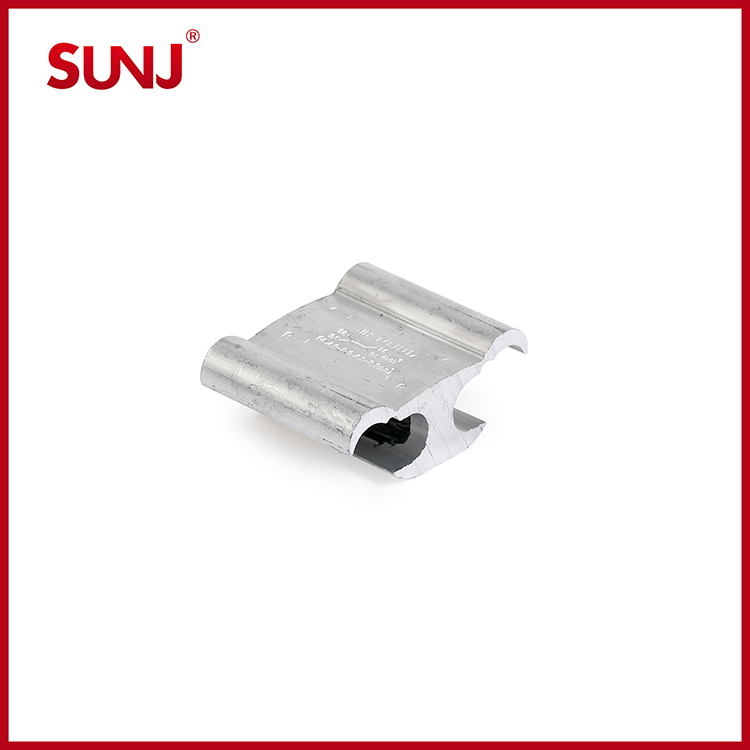

A dead end strain clamp is a mechanical fitting used in overhead power lines. It’s designed to anchor the conductor at the end or corner of the line. This type of tension clamp grips the wire tightly and transfers mechanical load to the pole or tower.

There are several styles, including:

-

Bolted type strain clamp

-

Wedge type strain clamp

-

Preformed dead end clamp

Each design is tailored to specific conductor types and mechanical loading conditions. Whether you're working with ACSR, copper or ABC cables, these clamps provide secure tensile support. If you're sourcing a China Dead End Strain Relief Clamp, many manufacturers offer solutions tested to ANSI C119.4, IEC 61284 or ISO 9001 quality standards - ensuring both cost effectiveness and reliable long-term performance.

Why Dead End Strain Clamps Matter

These clamps play a crucial role in line safety.

They:

-

Hold full wire tension

-

Prevent sagging or slippage

-

Ensure stability under wind and extreme weather

-

Fit multiple cable types (ACSR, copper, aluminum)

-

Lower maintenance needs

Designed to meet international utility standards such as IEC 61238-1 and IEEE 837, a high quality China Dead End Clamp ensures reliable performance in harsh environmental conditions such as UV exposure, high winds and salt spray. It's an essential component for any overhead line project that requires mechanical strength, electrical reliability and safety compliance.

Applications of Dead End Strain Clamps

You’ll find these clamps in many settings:

-

Overhead distribution and transmission lines

-

ABC cable networks

-

ADSS and OPGW fiber optic lines

-

Railway electrification systems

-

Industrial and urban power grids

A strain clamp for ABC cable is especially popular in insulated conductor systems for cities and rural networks.

Dead End Strain Clamp vs. Dead End Clamp

While the terms sound similar, they’re not quite the same.

| Feature | Dead End Strain Clamp | Dead End Clamp |

| Main use | Handles full line tension | Primarily for end anchoring |

| Structure | Bolted, wedge, or preformed | May be simpler or less load-bearing |

| Application | High-voltage or tensioned lines | Low-voltage or static ends |

| Function | Transfers load to pole or tower | Holds cable end in place |

| Conductor compatibility | Suitable for ACSR, AAAC, ABC, or OPGW cables | Usually limited to low-load copper or aluminum wires |

| Mechanical load rating | Designed to withstand high tensile stress (e.g. >70 kN) | Limited mechanical capacity, often non-load bearing |

| Standards compliance | Typically meets ANSI C119.4, IEC 61284, or IEEE 837 | May not require high-load or electrical certification |

| Installation complexity | May require torque tools, tension measurement, or specific spacing | Usually simple hand installation with minimal alignment |

Yes, we provide customized services to meet your specific needs. As a professional Electric Power Fittings manufacturer, we offer tailored solutions including custom designs, material selection, sizes, and operational features.

Our R&D capability is supported by full industry chain management, ensuring control from raw materials to product design and processing. We deliver high-quality Electric Power Fittings Products, and tailored solutions to meet customer needs.

SUNJ has an ISO9001-certified quality management system and an ISO14001-certified environmental management system! Our products has passed IEC 61238, IEC 61284, NFC 33042 standard certification. Our products deliver consistent performance you can trust.

SUNJ offers a wide range of solutions, including aerial overhead line fittings, ABC accessories, polymer insulators, lightning Arresters, Drop-out Fuse Cutouts, Disconnect Switch, Auto-iRecloser, SF6 Gas Circuit Breaker. Designed for reliability and performance, our products support power transmission, equipment protection, and grid automation.